TESTS ON BITUMEN

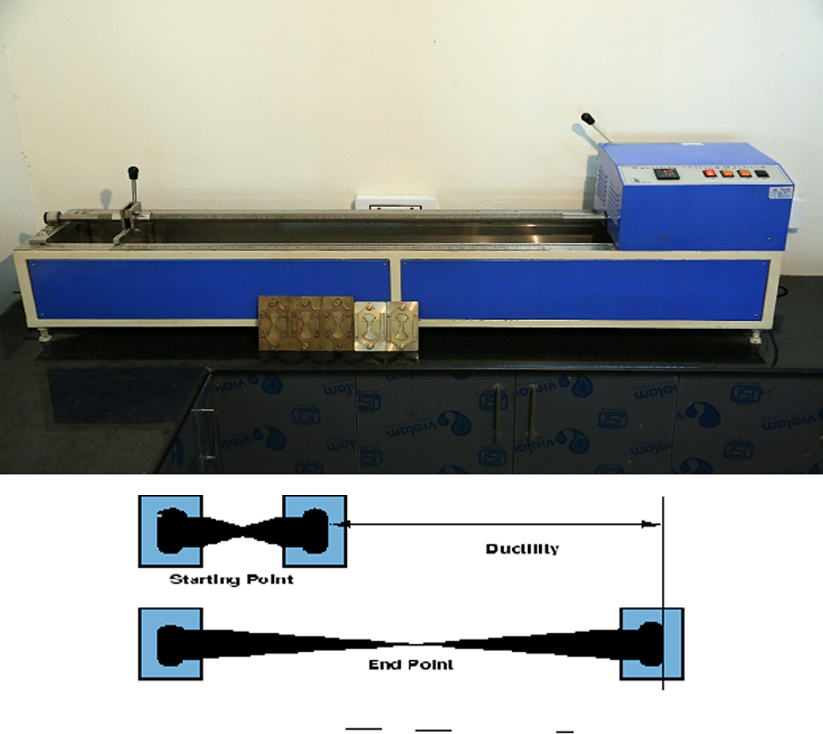

Ductility

This test is done as per IS: 1208 – 1978.The ductility of a bituminous material is measured by the distance in cm to which it will elongate before breaking when a standard briquette specimen of the material is pulled apart at a specified speed and a specified temperature.

Procedure:

- i) The bitumen sample is maintained to a pouring temperature (75°C to 100°C) and poured into the mould assembly and placed on a brass plate, where a solution of glycerin or soap solution is applied at all surfaces of briquette mould exposed to bitumen.

- ii) After the sample is poured to the mould, thirty to forty minutes the entire assembly is placed in a water bath at 27°C.

- iii) Then the sample is removed from the water bath maintained at 27°C and excess bitumen material is cutoff by leveling the surface using hot knife.

- iv) After trimming the specimen, the mould assembly containing sample is replaced in water bath maintained at 27°C for 85 to 95 minutes. Then the sides of mould are removed and the clips are carefully booked on the machine without causing any initial strain. Two or more specimens may be prepared in the moulds and clipped to the machine so as to conduct these test simultaneously.

- v) The pointer is set to read zero. The machine is started and the two clips are thus pulled apart horizontally.

- vi) While the test is in operation, it is checked whether the sample is immersed in water at depth of at least 10 mm.

Uses:

To determine the ductility of distillation residue of cutback bitumen, blown type bitumen and other bituminous products.