Tests on Aggregate

Shape Test

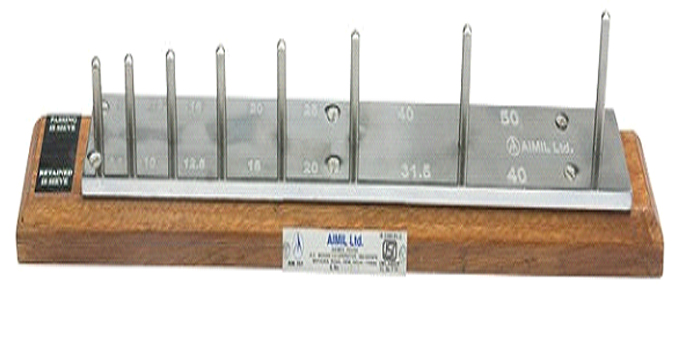

1. Elongation Index Value: Test is done as perIS:2386-Part 1-1963.

Procedure:

- i) The sample is sieved through IS sieve specified in Table shown below.

| Size of aggregate | Thickness Gauge * | Length Gauge + | ||||||

|

Passing through IS Seive

(1) |

Retained through IS Seive

(2) |

(3) mm |

(4) mm |

|||||

|

63-mm |

50-mm |

33.90 |

- |

|||||

|

50-mm |

40-mm |

27.00 |

81.0 |

|||||

|

40-mm |

25-mm |

19.50 |

58.5 |

|||||

|

31.5-mm |

25-mm |

16.95 |

- |

|||||

|

25-mm |

20-mm |

13.50 |

40.5 |

|||||

|

20-mm |

16-mm |

10.80 |

32.4 |

|||||

|

16-mm |

12.5-mm |

8.55 |

25.6 |

|||||

|

12.5-mm |

10-mm |

6.75 |

20.2 |

|||||

|

10-mm |

6.3-mm |

4.89 |

14.7 |

|||||

|

* This dimensions is equal to 0.6 times mean sieve size.

+ This dimensions is equal to 1.8 times mean sieve size. |

||||||||

- ii) A minimum of 200 pieces of each fraction is taken and weighed.

- iii) In order to separate elongated materials, each fraction is then gauged individually for length in the length gauge.

- iv) The pieces of aggregate from each fraction tested which could not pass through the specified gauge length with its long sides elongated are collected separately to find the total weight of aggregate retained on the length gauge from each fraction.

- v) 5. The total amount of elongated material retained by the length gauge is weighed to an accuracy of 0.1% of the weight of sample.

Uses:

To determine shape of aggregate.

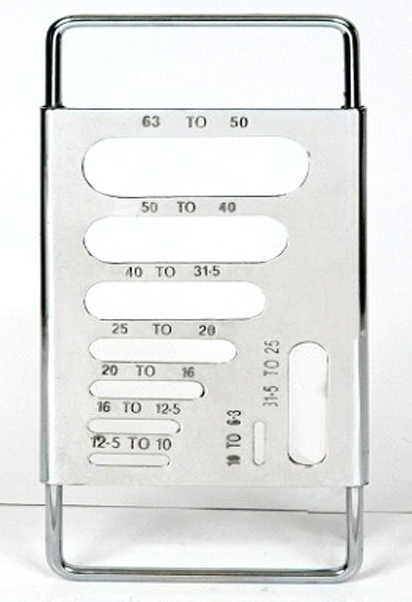

2. Flakiness Index Value : Test is done as perIS:2386-Part 1-1963.

Preparation sample

Surface dry samples is used for the test. A minimum number of 200 pieces of any specified fraction is required to do the test.

Procedure:

- i) The sample is sieved through IS sieve specified in Table shown below.

| Size of aggregate | Thickness Gauge * | Length Gauge + | ||||||

|

Passing through IS Seive

(1) |

Retained through IS Seive

(2) |

(3) mm |

(4) mm |

|||||

|

63-mm |

50-mm |

33.90 |

- |

|||||

|

50-mm |

40-mm |

27.00 |

81.0 |

|||||

|

40-mm |

25-mm |

19.50 |

58.5 |

|||||

|

31.5-mm |

25-mm |

16.95 |

- |

|||||

|

25-mm |

20-mm |

13.50 |

40.5 |

|||||

|

20-mm |

16-mm |

10.80 |

32.4 |

|||||

|

16-mm |

12.5-mm |

8.55 |

25.6 |

|||||

|

12.5-mm |

10-mm |

6.75 |

20.2 |

|||||

|

10-mm |

6.3-mm |

4.89 |

14.7 |

|||||

|

* This dimensions is equal to 0.6 times mean sieve size.

+ This dimensions is equal to 1.8 times mean sieve size. |

||||||||

- ii) A minimum of 200 pieces of each fraction is taken and weighed.

- iii) In order to separate flaky materials, each fraction is then gauged individually for thickness on a thickness gauge.

- iv) The total amount of flaky material passing the thickness gauge is weighed to an accuracy of 0.1% of the weight of sample.

Uses:

To determine shape of aggregate.